Over fifty years have passed since the invention of computer numerical control machining. Numerous devices have been made possible by its high capacity for automation and precision since then. This advanced technology has become an integral part of the global industrial DNA across numerous industries, including manufacturing, automotive, aerospace, and medical precision.

To put it briefly, CNC machining is a process that uses a computer to automate and operate a machine tool. These machines can carry out extremely intricate and precise tasks on a workplace with very little assistance from humans. These days, CNC is widely utilized in industrial businesses and offers a number of advantages. Turning, milling, drilling, and grinding services are just a few of the machining procedures that use it. Additionally, it is employed in a variety of industries, some of which have very strict production specifications, such the prototyping of aeronautical part.

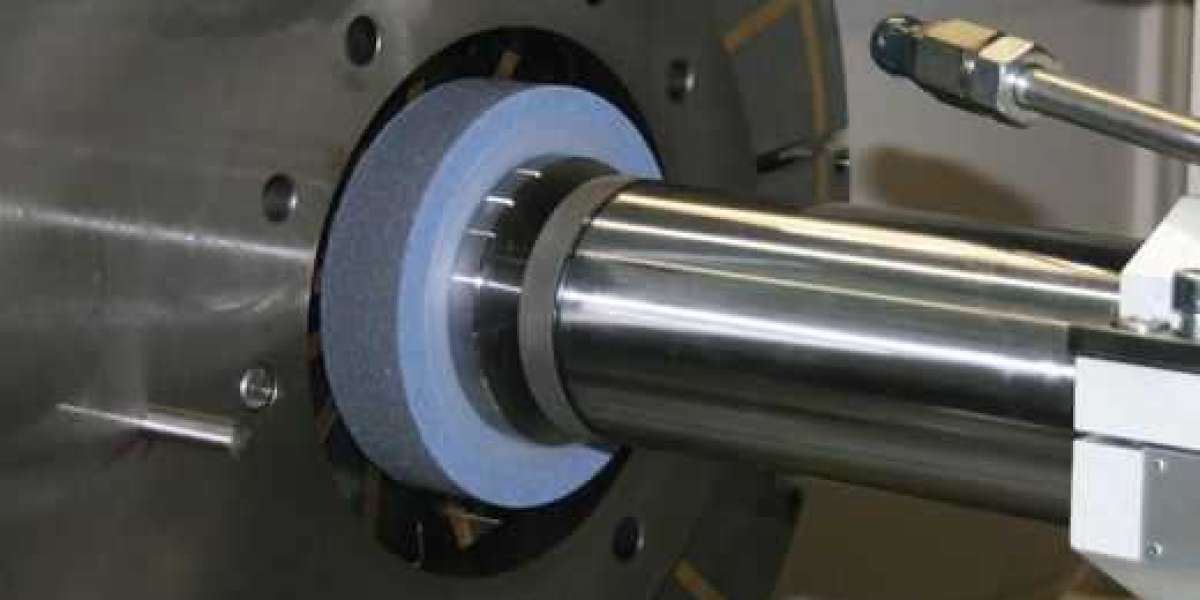

Professional machinists use a machine to remove or form metal in traditional machining. This is carried out in compliance with the guidelines that engineers and designers have supplied. They employ a variety of cutting tools, as well as turn wheels, dials, switches, chucks, and vices. Precision machining serves the same purpose as traditional milling, boring, grinding services, drilling, cutting, and other metal shaping and removal operations. It is code-driven, automated, and created by programmers.

The first time cutting, it is roughly as precise as the 500 widths. It is widely utilized in digital production and is adaptable to varied materials and revisions. Traditional machining has mostly been replaced by this sort of machining, which is far more precise. For maximum accuracy, it uses mathematical coordinates and computational power to accomplish the same goal. Computer numerical control typically uses Cartesian coordinates.

By subtracting and removing material, CNC machining uses subtractive techniques to machine feedstock to its final shape. Metal stock is formed into new materials with variable tapers, diameters, and shapes after holes are drilled, lots and paths are bored, and new materials are formed. Shapes are produced in subtractive manufacturing by subtracting material. Other forms, like additive manufacturing, are in contrast to this. Among the many materials that can be used with CNC precision machining are metals, polymers, wood, glass, foam, and other composite materials. Since it allows designers and engineers to create goods with efficiency and precision, CNC machining has become a popular choice across industries.

Last but not least, CNC machining is especially useful for producing unique, one-off items or providing a customer with a customized update. Its mechanical qualities are also attainable. All of the desired mechanical qualities of the selected metal or plastic are preserved by cutting away from the bulk material. The fact that milling and turning are very precise and repeatable procedures is the best part of employing CNC machining services. Depending on the various requirements, all of these can be accomplished. Remember that the CNC machining process uses software that falls into three categories: CAD software, CAM software, and CAE software. Make sure to learn more about how each operates.

Search

Popular Posts