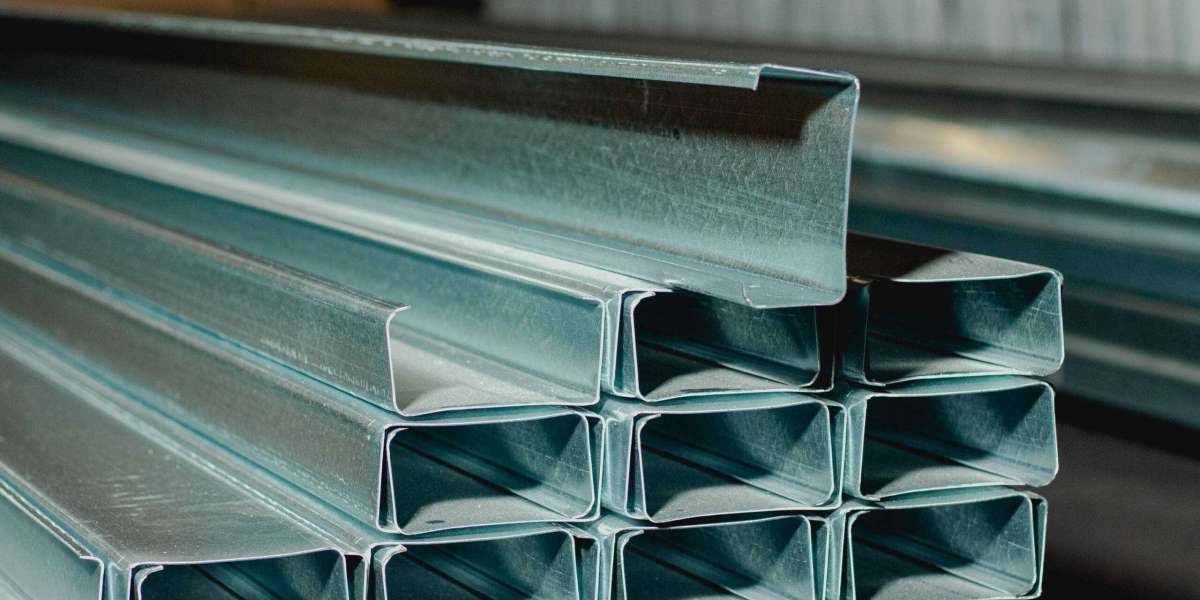

C purlins are important structural components that are extensively used in roofing and wall framing for residential, commercial, and industrial buildings. They are the principal support for roof platforms, wall cladding, and ceilings.

Even though high-quality materials are still important, proper installation and connection techniques are vital to ensure structural strength, stability, and longevity. An incorrect installation of your C purlin may lead to misalignment, structural failure, costly repairs, or safety hazards.

This uncomplicated guide will lead you through the process of selecting, installing, and effectively connecting C purlins, regardless of whether you are a contractor, DIY enthusiast, or site supervisor.

There are many factors that influence the important decision of selecting the best C purlin for your project. It is essential to assess the material and coating at the outset. For optimum corrosion protection, it is imperative to choose high-tensile galvanized steel and zinc coating Z350+.

Additionally, it is extremely important to consider the thickness and size prior to making this significant purchase. In reality, the standard section should be between 100mm and 350mm, although special sizes of up to 400mm are also available. The portion size and thickness must be in compliance with the local conditions, design capacity, and roof span, which is important to ensure.

The installation and connection of C purlins begin with the punching of openings. Standard purlins are equipped with pre-punched apertures in accordance with AISC center-to-center standards. In order to perforate non-standard purlins or those that lack pre-punched apertures, a specialized punching machine can be employed.

As soon as the hole perforation is finished, the C purlins should be aligned and lapped. Ensure that the lap joints are properly aligned to ensure that the loads are transferred equitably for lapped c connections. Using bottom flange bolts at the lap zone will ensure structural continuity.

The connections must be secured at this time. It is essential to use high-strength bolts, specifically M12 bolts for purlins between 100mm and 250mm and M16 bolts for purlins between 300mm and 350mm. All of the bolts must be tightened before applying loads, which is important.

The proper selection, installation, and connection of C purlins are vital to the structural integrity and longevity of roofing and wall framing systems. By following this straightforward guide and adhering to industry best practices, you can ensure safe, stable, and long-lasting structures.

It is essential to comply with manufacturer guidelines and national standards in order to achieve the best possible results. It is important to utilize professional-grade instruments for this expedition. Additionally, it is advantageous to seek the advice of structural engineers when uncertain.